Piston Motor Parts: A Comprehensive Guide to Quality Diesel Engine Components

In the competitive realm of diesel engine operations, understanding the intricacies of piston motor parts is crucial for achieving maximum performance and longevity. These components play a pivotal role in the engine's overall functionality and efficiency. In this article, we will delve deep into the world of pistons, their significance, common issues, and how to maintain optimal performance.

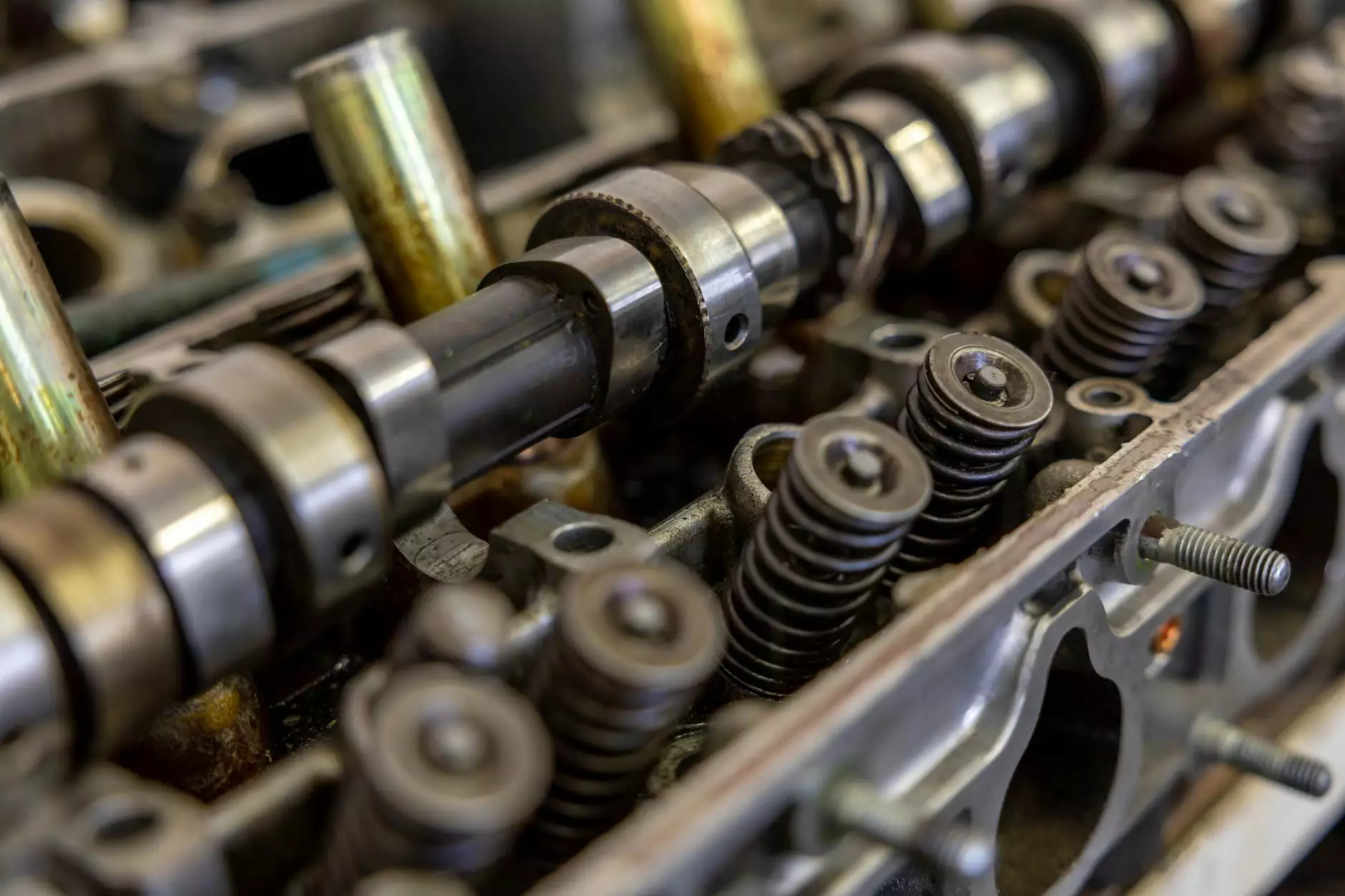

Understanding Piston Motor Parts

The piston is a component of reciprocating engines, pumps, and compressors, forming a crucial part of the internal combustion engine. They serve to transfer the pressure from the combustion of fuel into mechanical work.

Components That Make Up a Piston Motor

A typical piston motor consists of several key components:

- Piston: The primary component that moves up and down within the cylinder.

- Piston Rings: These ensure a proper seal between the piston and the cylinder wall.

- Piston Pin: This connects the piston to the connecting rod.

- Connecting Rod: This links the piston to the crankshaft, converting the piston's linear motion into rotational motion.

- Crankshaft: The component that translates the linear motion of the pistons into rotational energy.

The Importance of High-Quality Piston Motor Parts

Choosing high-quality piston motor parts is imperative for several reasons:

1. Enhanced Engine Performance

High-quality pistons provide a better seal and, therefore, improve combustion efficiency. This leads to enhanced overall engine performance, resulting in:

- Increased power output

- Improved fuel efficiency

- Reduced emissions

2. Durability and Longevity

Quality piston parts are designed to withstand extreme temperatures and pressures. This durability results in longer service life, reducing the frequency of repairs and replacements.

3. Cost-Effectiveness

Investing in high-quality components reduces the likelihood of catastrophic engine failures that can lead to costly repairs. In the long run, using superior parts can save you money.

Common Issues with Piston Motor Parts

Despite their robust design, piston motor parts can experience issues over time. Here are some common problems:

1. Piston Ring Wear

Piston rings can wear out due to friction and high temperatures, leading to poor sealing, loss of compression, and increased oil consumption.

2. Cracking or Scoring

When a piston becomes too hot or experiences excessive pressure, it may crack or score, which can lead to severe engine damage if not addressed promptly.

3. Piston Knock

Piston knock is a common problem that occurs when there is excessive clearance between the piston and the cylinder wall. This can create unwanted noise and may indicate a need for immediate attention.

Maintaining Your Piston Motor Parts

Proper maintenance of your piston motor parts is essential for optimal performance and longevity. Here are some maintenance tips:

1. Regular Oil Changes

Using high-quality oil and changing it regularly helps to reduce friction in the engine, prolonging the life of the piston and its components.

2. Monitoring Engine Temperature

Keep an eye on your engine temperature and ensure it stays within the optimal range. Overheating can severely damage pistons and other internal engine components.

3. Using Quality Fuels and Additives

Using high-quality fuel along with additives can help clean the fuel system and improve combustion efficiency, benefiting the pistons' performance.

Where to Buy Quality Piston Motor Parts

When sourcing piston motor parts, it's essential to choose reliable suppliers to ensure you receive authentic and durable products. Client Diesel offers a wide range of diesel engine parts and is known for their reliability and customer service.

The Role of Spare Parts Suppliers in the Industry

Spare parts suppliers play a vital role in the maintenance and repair of diesel engines. They are responsible for:

- Providing access to a variety of components, including hard-to-find parts.

- Offering expert advice on part compatibility and maintenance.

- Ensuring timely delivery of essential parts to minimize downtime.

The Benefits of Choosing the Right Supplier

Selecting a trusted supplier ensures that you receive:

- Authentic parts that meet manufacturer standards.

- Warranties on products to safeguard your investment.

- Competitive pricing and special offers.

Future Trends in Piston Motor Technology

The field of piston motors is rapidly evolving. Future trends include:

1. Improved Materials

Advancements in materials science are leading to the development of pistons that can withstand higher pressures and temperatures, improving engine performance and fuel efficiency.

2. Enhanced Engine Control Technologies

Emerging technologies in engine control systems enable more precise management of engine parameters, optimizing combustion and efficiencies in real time.

3. Electrification of Engines

As the automotive industry shifts toward electrification, understanding the integration of piston technology with electric systems will become paramount.

Conclusion

Understanding piston motor parts is essential for anyone involved in the maintenance or operation of diesel engines. By being aware of their significance, common issues, and maintenance techniques, you can ensure longevity and optimal performance of your engine. Always remember, investing in quality parts from reputable suppliers like Client Diesel can make a significant difference in your engine's efficiency and durability.

By keeping abreast of the latest trends and technologies in piston motor design and manufacturing, you can ensure that your engine remains competitive in an ever-evolving market. Empower yourself with knowledge and quality components, and you will maximize your investment in diesel engines.