Why Is It Necessary to Dry Grains Before Storage? A Critical Step for Farming Equipment and Crop Preservation

In the comprehensive realm of agricultural operations, especially within the domains of Farm Equipment Repair and Farming Equipment, proper post-harvest handling plays a pivotal role in safeguarding crop quality, maximizing yield, and prolonging the lifespan of farm machinery. Among these essential practices, drying grains before storage stands out as a fundamental step that significantly influences storage success, equipment maintenance, and overall farm profitability.

Introduction to Grain Drying: A Vital Agricultural Practice

Drying grains after harvest isn't merely about reducing moisture levels; it is a crucial step that ensures the grains' longevity, preserves their nutritional and commercial value, and prevents devastating issues like mold growth, insect infestation, and spoilage. For farmers and agricultural entrepreneurs utilizing advanced Farming Equipment and seeking Farm Equipment Repair solutions, understanding the importance of proper grain drying is vital.

The Science Behind Grain Moisture Content and Its Impact

The moisture content in harvested grains typically varies depending on crop type, harvest conditions, and maturity levels. Generally, grains contain enough water to support microbial activity and insect proliferation, which can lead to significant deterioration over time.

For example, wheat and corn are most stable when dried to moisture levels below 13-15%. Higher moisture levels can accelerate biological activity, leading to spoilage, deteriorated quality, and loss of economic value. Therefore, the why is it necessary to dry grains before storage question is rooted in the need to reach this critical moisture threshold.

Key Reasons Why Drying Grains Is Essential Before Storage

1. Prevention of Mold and Fungal Growth

One of the most immediate risks of storing moist grains is mold formation, which can produce mycotoxins harmful to both human and animal health. Mold thrives in humid environments, and even small increases in moisture content can facilitate rapid fungal proliferation, compromising entire grain batches.

2. Reducing Insect Infestations

Insects such as weevils and beetles are common pests that target stored grains. High moisture levels attract these pests and provide suitable conditions for their reproduction. Dry grains create an inhospitable environment for pests, ensuring the integrity of the stored crop.

3. Enhancing Storage Longevity and Quality Preservation

Properly dried grains maintain their physical and nutritional characteristics longer. This extends their shelf life, preserves taste, nutritional value, and marketability, which directly benefits farmers and suppliers relying on top-quality produce for competitive sales.

4. Optimizing Farm Equipment Efficiency and Longevity

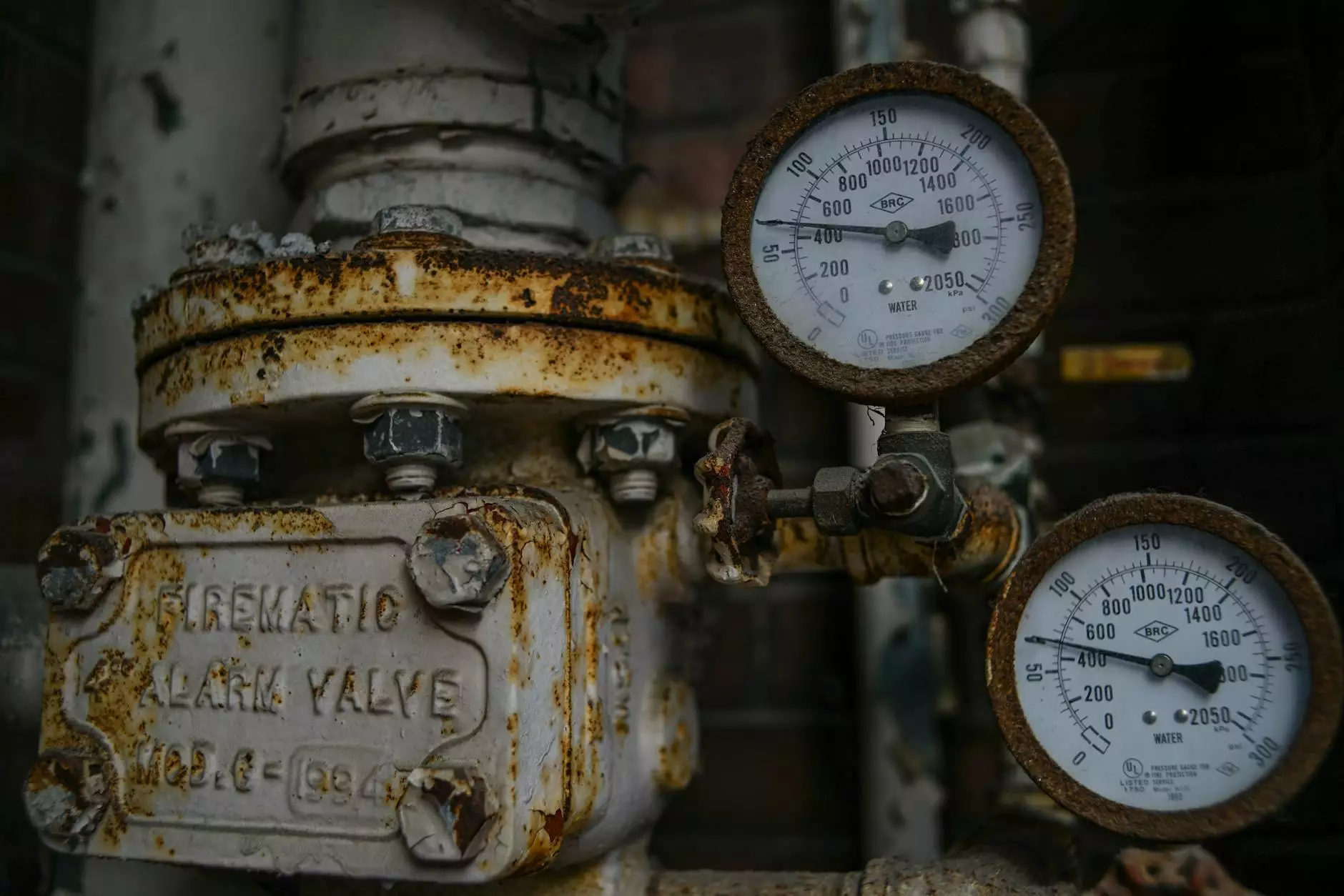

Farm machinery used in storage facilities, such as grain dryers, elevators, and conveyors, are engineered to operate efficiently when handling low-moisture grains. Excess moisture can lead to clogging, corrosion, and wear on equipment components, increasing repair costs and downtime.

5. Cost Savings and Economic Benefits

By reducing the risk of spoilage and pest infestation through effective drying, farmers save money associated with crop loss, repair of damaged equipment, and potential health hazards. Dry grains also fetch better prices in the market, boosting overall farm profitability.

How to Effectively Dry Grains: Techniques and Equipment

Employing advanced Farming Equipment solutions such as grain dryers, aeration systems, and moisture meters are integral to achieving optimal drying results. These tools allow farmers to monitor and control moisture levels precisely.

- Mechanical Grain Dryers: Use heated air to reduce moisture quickly and uniformly, suitable for large-scale operations.

- Natural Air Drying: Utilize ambient conditions, optimal in dry, hot climates; less energy-intensive but slower.

- Aeration Systems: Circulate dry air through stored grains to gradually decrease moisture levels, good for maintaining consistent dryness.

- Moisture Meters: Critical for monitoring moisture content and ensuring grains reach the desired dryness before storage.

Best Practices for Grain Drying in Modern Farms

Implementing best practices ensures effective drying while maintaining the quality of your crops:

- Harvest at the Right Maturity: Harvest crops at optimal maturity to minimize initial moisture content.

- Selective Drying: Use tailored drying approaches based on crop type, ambient conditions, and storage duration.

- Monitor Moisture Levels: Regularly test grains during and after drying to avoid over-drying or under-drying.

- Maintain Equipment Properly: Regular maintenance of grain dryers and aeration systems ensures efficiency and longevity of your Farm Equipment.

- Control Storage Environment: Keep storage facilities dry, clean, and well-ventilated to complement drying efforts.

The Role of Proper Grain Drying in Overall Farm Management

Effective grain drying influences every facet of farm management:

- It supports compliance with safety and food quality standards.

- Reduces post-harvest losses significantly.

- Ensures smoother operations of storage and handling equipment.

- Facilitates better bargaining power with buyers, based on superior quality.

- Enhances sustainability by reducing waste and energy consumption when performed correctly.

Choosing the Right Equipment and Partner for Grain Drying

When investing in Farming Equipment or seeking Farm Equipment Repair services, select providers that understand the complexities of grain drying processes. Companies like TSG C Inc. specialize in offering innovative solutions, reliable equipment, and expert repair services that help farmers optimize their operations from harvesting to storage.

Conclusion: The Critical Importance of Properly Dried Grains Before Storage

In today's competitive agricultural landscape, understanding why it is necessary to dry grains before storage is more vital than ever. Proper drying not only preserves the quality, safety, and market value of the harvest but also protects the investment in farm equipment, reduces costs, and enhances overall productivity.

Farmers and agricultural businesses committed to excellence must prioritize grain drying as an integral part of their post-harvest management. Leveraging the right Farming Equipment and maintenance services ensures that this process is efficient, effective, and sustainable for many seasons to come.

Remember, successful farming is not just about the harvest; it is about the careful, strategic management of every step—especially drying grains before storage. It is an investment in quality, safety, and future profitability that no farmer should overlook.